What is Design for Manufacturing or DFM?

Design for Manufacturing (DFM) is the process of designing parts, components or products for ease of manufacturing with an end goal of making a better product at a lower cost. This is done by simplifying, optimizing and refining the product design. The acronym DFMA (Design for Manufacturing and Assembly) is sometimes used interchangeably with DFM.

Five principles are examined during a DFM. They are:

o Process

o Design

o Material

o Environment

o Compliance/Testiing

Ideally, DFM needs to occur early in the design process, well before tooling has begun. In addition, properly-executed DFM needs to include all the stakeholders — engineers, designers, contract manufacturer, moldbuilder and material supplier. The intent of this “cross-functional” DFM is to challenge the design — to look at the design at all levels: component, sub-system, system, and holistic levels — to ensure the design is optimized and does not have unnecessary cost embedded in it.

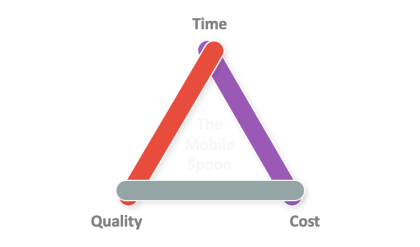

The following chart offers an excellent visual representation of the effect of an early DFM. As the design progresses through the product life cycle, changes become more expensive, as well as more difficult to implement. Early DFM allows design changes to be executed quickly, at the least expensive location.

Pulling stakeholders together early in the design process is easier if you’re developing a new product, but even if you’re dealing with an established product, challenging the original design is a necessary element of a thorough DFM. Too often, mistakes in a design are repeated by replicating a previous design. Question every aspect of your design.

Ø Look at the original drawings.

Ø Tear down the product.

Ø Look at competitive and near-neighbor products, as well as lead users such as medical and automotive.

Ø Talk to your contract manufacturer — who may have solved the problem with a different customer?

Ø Has someone else solved this problem a different way?

Ø Is there a way to make it better?

A lot of thought, time and effort go into a DFM. Jeff Tadin, our senior product development engineer, has almost 30 years of experience with product development, design and manufacturing. Today, he’s going to walk us through a hypothetical DFM process using a basic computer mouse (this mouse was not produced by East West Manufacturing.)